The UF3000 prober is a high-precision piece of equipment widely used in semiconductor wafer testing. It plays a critical role in ensuring the electrical functionality of integrated circuits (ICs) before they are finalized and packaged. This user guide provides a comprehensive look at how to properly set up, operate, maintain, and troubleshoot the UF3000 prober, enabling users to maximize its performance and longevity.

Understanding the UF3000’s user manual is crucial not only for efficient operation but also for avoiding common errors that can occur in semiconductor testing environments. This guide will cover everything from initial setup and calibration to advanced features, ensuring that operators can handle the prober with confidence.

Overview of UF3000 Prober

The UF3000 is a highly versatile and reliable wafer prober designed to meet the demands of high-volume and precision-driven testing environments. Below is a table outlining the key technical specifications of the UF3000 prober:

| Feature | Specification |

|---|---|

| Wafer Size Support | 200mm (8”) and 300mm (12”) |

| Alignment Accuracy | ±2 microns |

| Z-Axis Accuracy | ±1 micron |

| Maximum Chuck Temperature | 200°C |

| Minimum Chuck Temperature | -40°C |

| Probe Card Compatibility | Universal compatibility with various probe card types |

| Throughput Rate | Up to 300 wafers per hour |

| Software Compatibility | Supports UF Software Suite and third-party integrations |

The UF3000 is typically used in wafer-level reliability (WLR) testing, parametric testing, and functional testing of semiconductor devices. Its advanced alignment capabilities, high throughput, and precision make it ideal for use in both research and production environments.

Core Components:

- Wafer Chuck: Holds the wafer during testing and can be heated or cooled depending on the test requirements.

- Probe Card Holder: Supports various probe cards used to make contact with wafer pads for testing.

- Z-Axis Control: Allows for fine adjustments of the wafer and probe card alignment.

1.Getting Started with the UF3000 Prober

Unboxing and Setup:

Before operating the UF3000, it is important to follow a systematic unboxing and setup procedure to ensure all components are intact and properly configured. Follow these steps:

1.1 Unboxing Checklist:

- Inspect the packaging for signs of damage.

- Check that all components listed in the manual are included (probe card holder, wafer chuck, cables, manuals, software discs).

- Ensure that safety equipment such as grounding straps and ESD protection gear is available.

1.2 Setup Instructions:

- Positioning the Prober: Place the prober on a stable, vibration-free surface in a controlled environment with appropriate temperature and humidity levels.

- Electrical Connections: Ensure the prober is connected to a stable power source. Use the provided power cable and connect it to a grounded outlet.

- Connecting Peripheral Devices: Attach any external devices, such as a PC or monitor, to the UF3000. Connect the probe card holder and wafer handling arms as specified in the manual.

- Installing Software: If required, install the UF3000 software suite on the connected PC. Ensure all drivers are correctly installed.

1.3 Powering On the Prober:

- Verify that all connections are secure.

- Power on the prober by switching on the main power supply.

- Wait for the initialization sequence to complete, which will be displayed on the connected monitor.

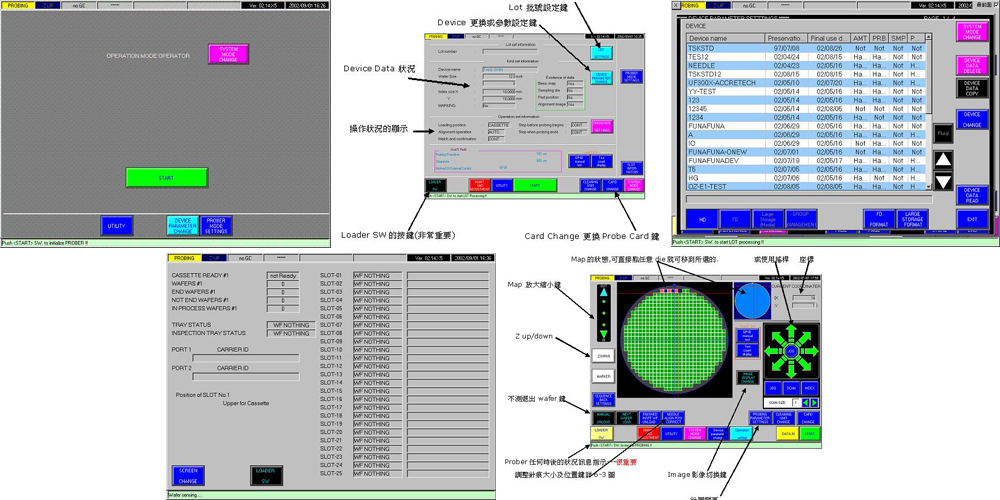

1.4 Basic Navigation: The UF3000 interface includes various control panels for navigation:

- Main Control Panel: Controls for wafer loading, chuck movement, and test sequence initiation.

- Status Monitor: Displays real-time data on wafer positioning, alignment accuracy, and test progress.

2. Operating the UF3000 Prober

Proper operation of the UF3000 requires a solid understanding of its configuration and testing procedures. Below are detailed instructions to help operators navigate the core operational functions.

Prober Configuration:

To prepare the UF3000 for a testing session, follow these steps:

2.1 Load the Probe Card:

- Install the probe card onto the probe card holder.

- Ensure that the probe tips are clean and aligned with the wafer contact pads.

2.2 Wafer Loading:

- Load wafers onto the chuck using the wafer-handling arm.

- Ensure that the wafers are properly aligned with the chuck to prevent damage or testing errors.

2.3 Test Configuration:

- Configure the testing parameters in the software, including temperature settings, test voltage, and current thresholds.

- Save the configuration as a preset for future use.

Executing a Test:

2.1 Run the Test:

- Initiate the test sequence through the software interface.

- The prober will move the wafer into position under the probe card, and the test will begin automatically.

- The test sequence will run based on the preset parameters, and data will be collected and displayed in real-time.

2.2 Monitoring Test Progress:

- Monitor the wafer’s position and the probe tips' alignment through the real-time status monitor.

- If misalignment occurs, pause the test and realign the probe card or wafer manually.

2.3 Saving and Exporting Data:

- Once the test is complete, save the test data in the desired format (e.g., CSV, XML).

- Export the data to external storage devices or upload it directly to a networked server.

3. Calibration and Alignment Procedures

Accurate calibration is essential for ensuring precise test results. The UF3000 offers both manual and automated calibration options to maintain optimal performance.

Importance of Regular Calibration:

Regular calibration helps maintain the accuracy of the prober’s measurements and prevents drift that can lead to incorrect test results. Operators should perform calibration routines:

- After probe card replacements.

- After significant temperature fluctuations.

- Following extended periods of inactivity.

Manual Calibration Steps:

- 3.1 Probe Card Alignment:

- Adjust the X, Y, and Z-axis positioning of the probe card to ensure the probe tips are precisely aligned with the wafer pads.

- Use the manual calibration interface on the software to fine-tune positioning.

- 3.2 Z-Axis Alignment:

- Ensure that the probe tips make optimal contact with the wafer by adjusting the Z-axis (vertical) alignment.

- Use the “Tip-to-Die” calibration mode to measure the contact force between the probe tips and the wafer pads.

Automated Calibration Tools:

The UF3000 also features an automated calibration option, which can streamline the process:

- Auto-Alignment Tool: The system uses vision-based alignment to automatically adjust the probe card’s position.

- Tip Calibration: Automatically calibrates the Z-axis using the built-in force sensors to ensure consistent probe tip contact.

Operators should run these calibration tools regularly, especially when switching between different wafer sizes or test types.

Troubleshooting Common Issues

Even with proper operation, issues can arise during the use of the UF3000 prober. Identifying and resolving these problems quickly is essential for minimizing downtime and ensuring the accuracy of test results. Below is a comprehensive guide to troubleshooting common problems, organized into hardware and software categories.

Error Codes and Their Meanings:

The UF3000 is equipped with a diagnostic system that displays error codes when problems are detected. Some of the most common error codes and their meanings are listed below:

| Error Code | Description | Solution |

|---|---|---|

| E101 | Probe card misalignment | Recalibrate probe card position; check for physical obstructions. |

| E203 | Wafer not detected on chuck | Ensure wafer is properly loaded and aligned on the chuck. |

| E307 | Temperature sensor malfunction | Verify sensor connections; replace faulty sensor if needed. |

| E404 | Communication error with control software | Check software connections; restart system or reconfigure IP settings. |

Hardware-Related Issues:

1. Probe Card Misalignment:

- Problem: The probe card is not making proper contact with the wafer.

- Solution: Recalibrate the X, Y, and Z-axis alignment of the probe card. Ensure there are no obstructions or debris on the probe tips or wafer surface.

2. Wafer Loading Problems:

- Problem: The wafer is not properly loaded or is slipping off the chuck.

- Solution: Check the chuck vacuum pressure and ensure that the wafer handling arm is functioning properly. Clean the chuck surface and reload the wafer.

3. Temperature Control Issues:

- Problem: The prober is unable to maintain the desired chuck temperature.

- Solution: Verify that the heating/cooling elements are functioning correctly. Inspect temperature sensors and replace them if necessary.

Software-Related Problems:

1. Communication Errors:

- Problem: The prober fails to communicate with the control software.

- Solution: Check all network and cable connections between the UF3000 and the PC. Restart both the prober and the software. Reconfigure network settings if necessary.

2. Software Freezing or Crashing:

- Problem: The control software becomes unresponsive or crashes during operation.

- Solution: Ensure the software is up to date and compatible with the prober’s firmware version. If the issue persists, reinstall the software or contact technical support.

Maintenance Guidelines

Proper maintenance of the UF3000 prober is crucial for extending its lifespan and maintaining high test accuracy. Both daily and long-term maintenance routines should be followed to ensure optimal performance.

Daily and Weekly Maintenance Routines:

Operators should perform basic maintenance tasks at the end of each testing cycle to ensure the UF3000 remains in good working condition. Key tasks include:

1. Cleaning the Wafer Chuck:

- Dust and debris can accumulate on the chuck surface, causing poor wafer adhesion or testing inaccuracies. Use an approved cleaning solution and a lint-free cloth to clean the chuck daily.

2. Inspecting the Probe Card:

- Check the probe tips for any signs of wear or contamination. Clean the probe tips gently with isopropyl alcohol to remove any residue.

3. Cable and Power Connection Check:

- Ensure that all cables and power connections are secure. Look for signs of wear on cables and replace them as necessary.

Long-Term Maintenance:

The UF3000 requires more extensive maintenance after prolonged use. This includes:

| Component | Maintenance Frequency | Action Required |

|---|---|---|

| Probe Card Replacement | Every 6 months (or as needed) | Replace worn or damaged probe cards to ensure consistent performance. |

| Chuck Calibration | Every 3 months | Perform a full chuck calibration using the automated calibration tools. |

| Firmware Updates | As available | Ensure the system firmware is up to date to benefit from the latest features and fixes. |

By adhering to these maintenance schedules, operators can prevent unexpected failures and ensure the UF3000 operates at peak efficiency.

The UF3000 prober is a powerful tool for semiconductor testing, offering precision, reliability, and versatility. By following this comprehensive guide, operators can ensure they are using the prober to its full potential. From setup and calibration to troubleshooting and maintenance, each section of this guide has been designed to help users master the key functions of the UF3000.

Regular maintenance, adherence to safety precautions, and proper use of the advanced features will ensure that the UF3000 continues to deliver accurate and efficient test results, making it an invaluable asset in any semiconductor testing environment.