The WJ-TEOS999 deposits doped or undoped silicon dioxide (SiO2) films, created from either the TEOS/Ozone or Silane/Oxygen CVD reaction. Examples of the broad range of application include shallow trench isolation, pre-metal dielectric, interlayer dielectric and numerous spacer oxides. Typically, the silicon dioxide film is doped with Boron, Phosphorus and/or Germanium.

In addition to films in the traditional silicon market, APCVD systems have found use in the MEMS, optical and solar markets.

WJ1000 system deposit doped or updoped silicon dioxide films , created from the TEOS CVD reaction.

The WJ1000 Film applications include shallow trench isolation, capacitor ILD, Bitline ILD, Gate ILD , Sidewall spacer , PSG passivation, IMD gap fill and capacitor core oxide.

Production-proven Performance

* Over 650 systems shipped to major fabs worldwide

* Demonstrated high productivity and reliability

Multi-generation Capability

* Capable of 100-mm, 125-mm, 150-mm and 200-mm wafer processing

* Process extendibility from 0.5 micron to 0.08 micron

* Characterized process models for Atmospheric Pressure processes

* SMIF/AGV compatible, complying with SEMI specifications

Superior Process Results

* Process muffle environment designed for process flexibility

-Three matched deposition chambers are environmentally controlled to provide continually repeatable film results

* High dopant incorporation in bulk film for best planarization

* High O3:R ratio or O2:R ratio in stability layer for as-deposited film stability

* High deposition temperature for superior film density

* High dopant incorporation without BPO4 crystals

* Two process chemistries on one system (TEOS 999 only)

-TEOS/Ozone or Silane/Oxygen CVD reations

Low Cost of Ownership

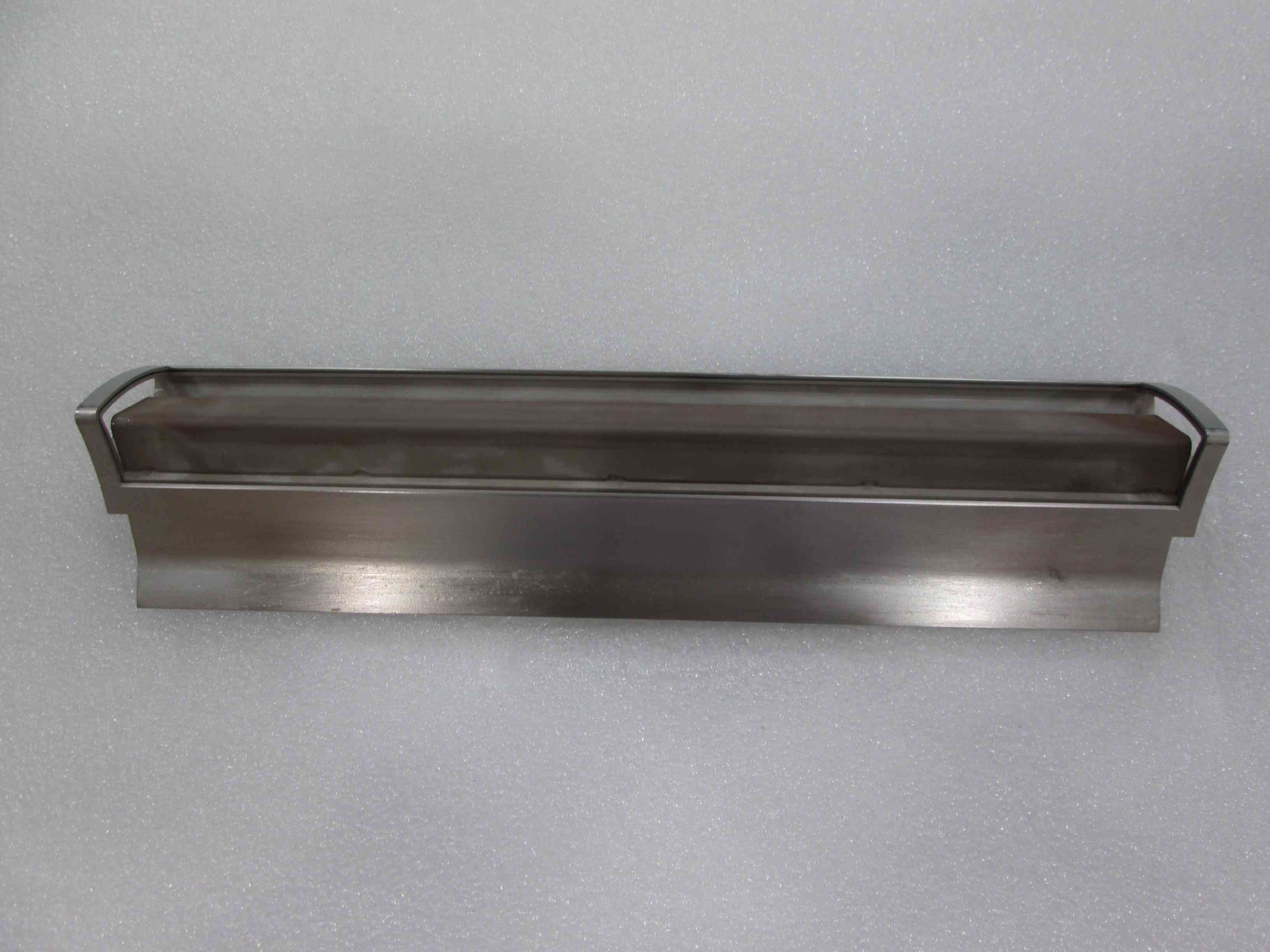

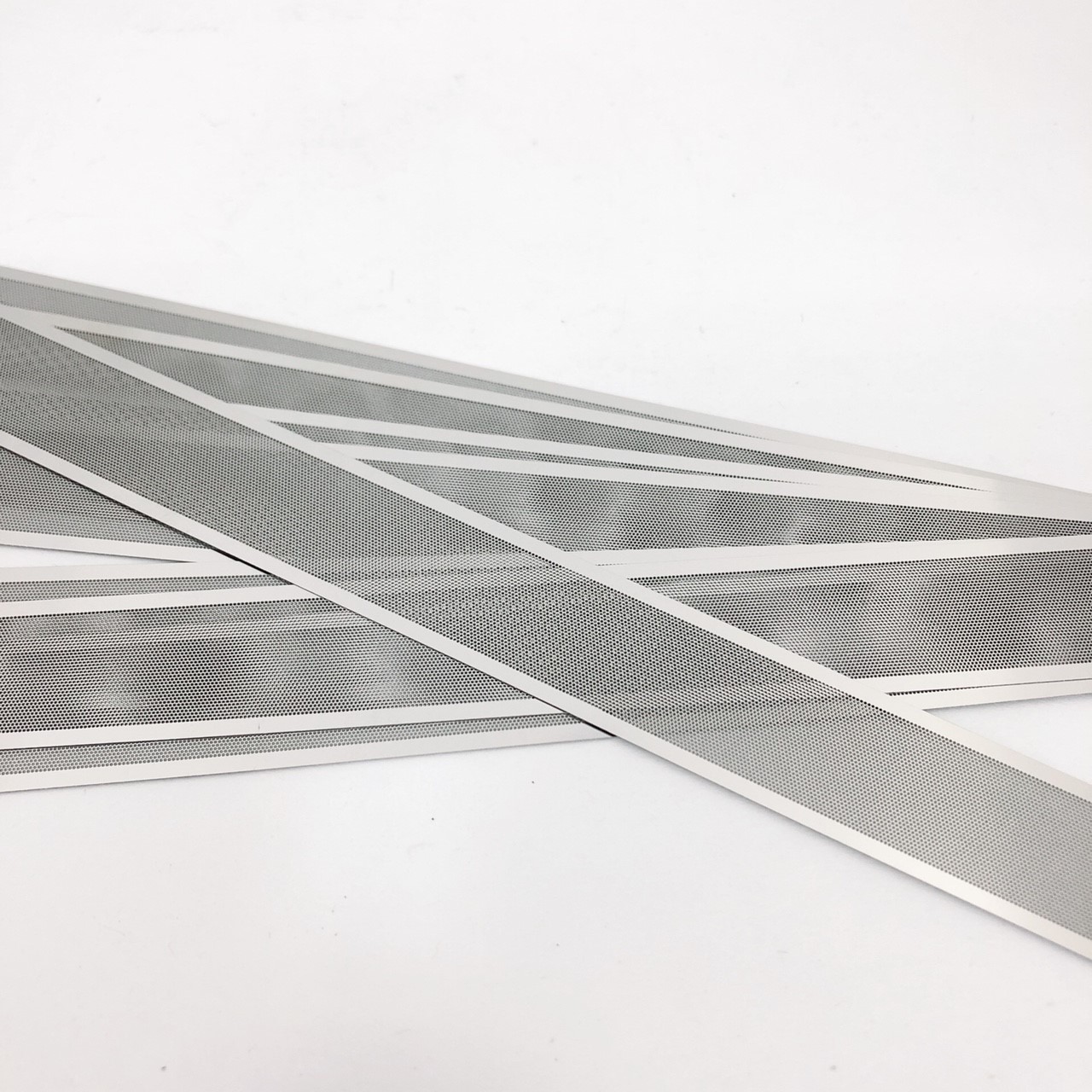

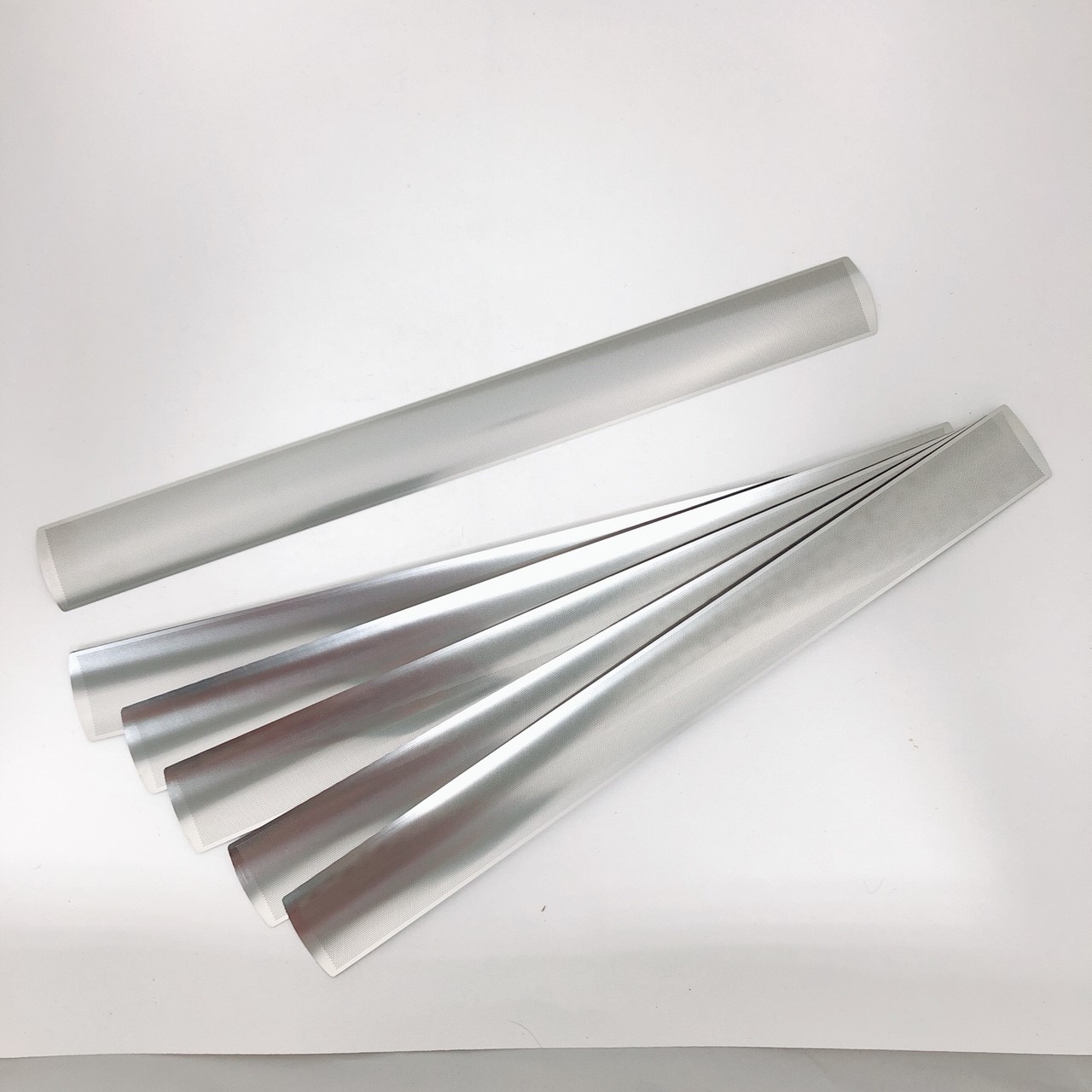

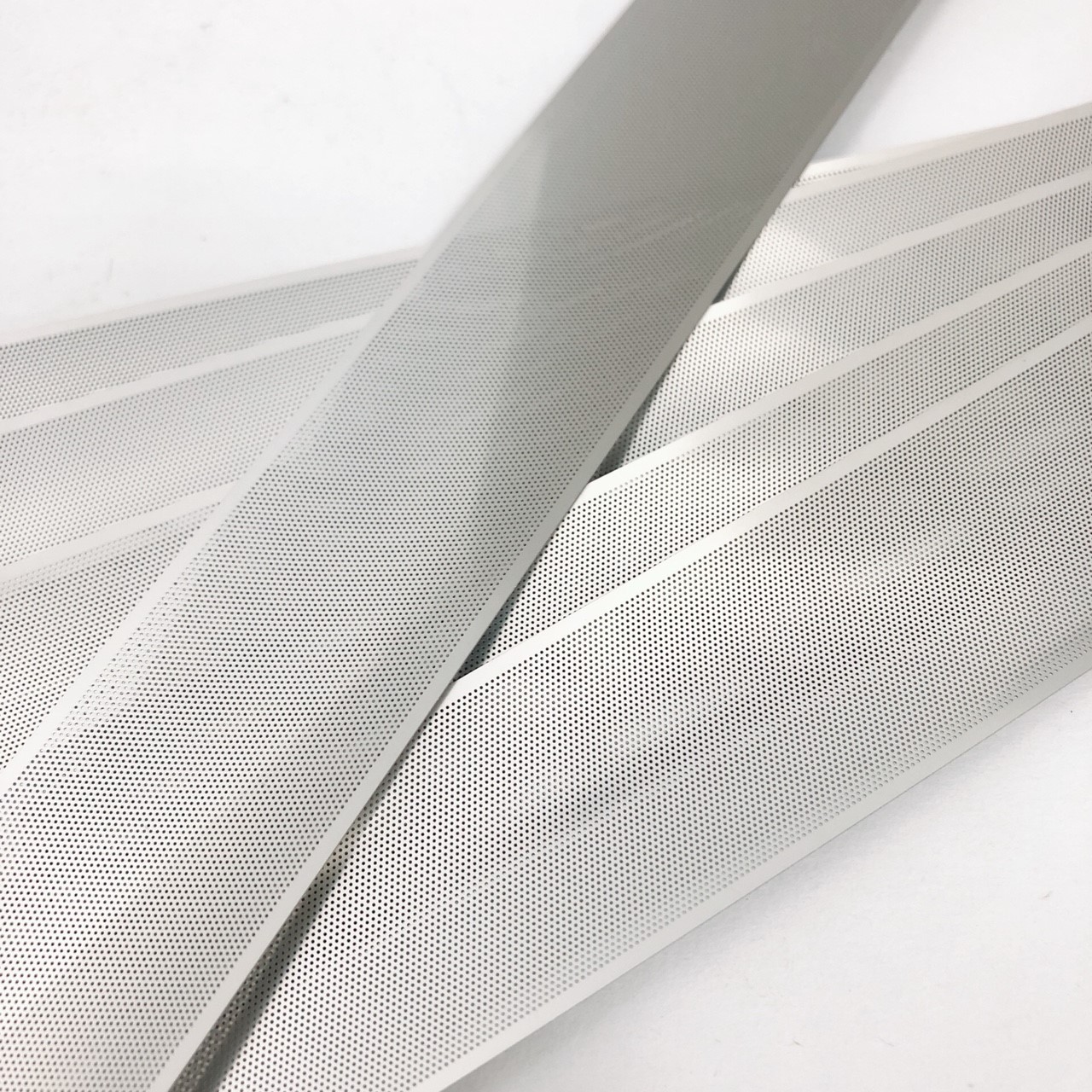

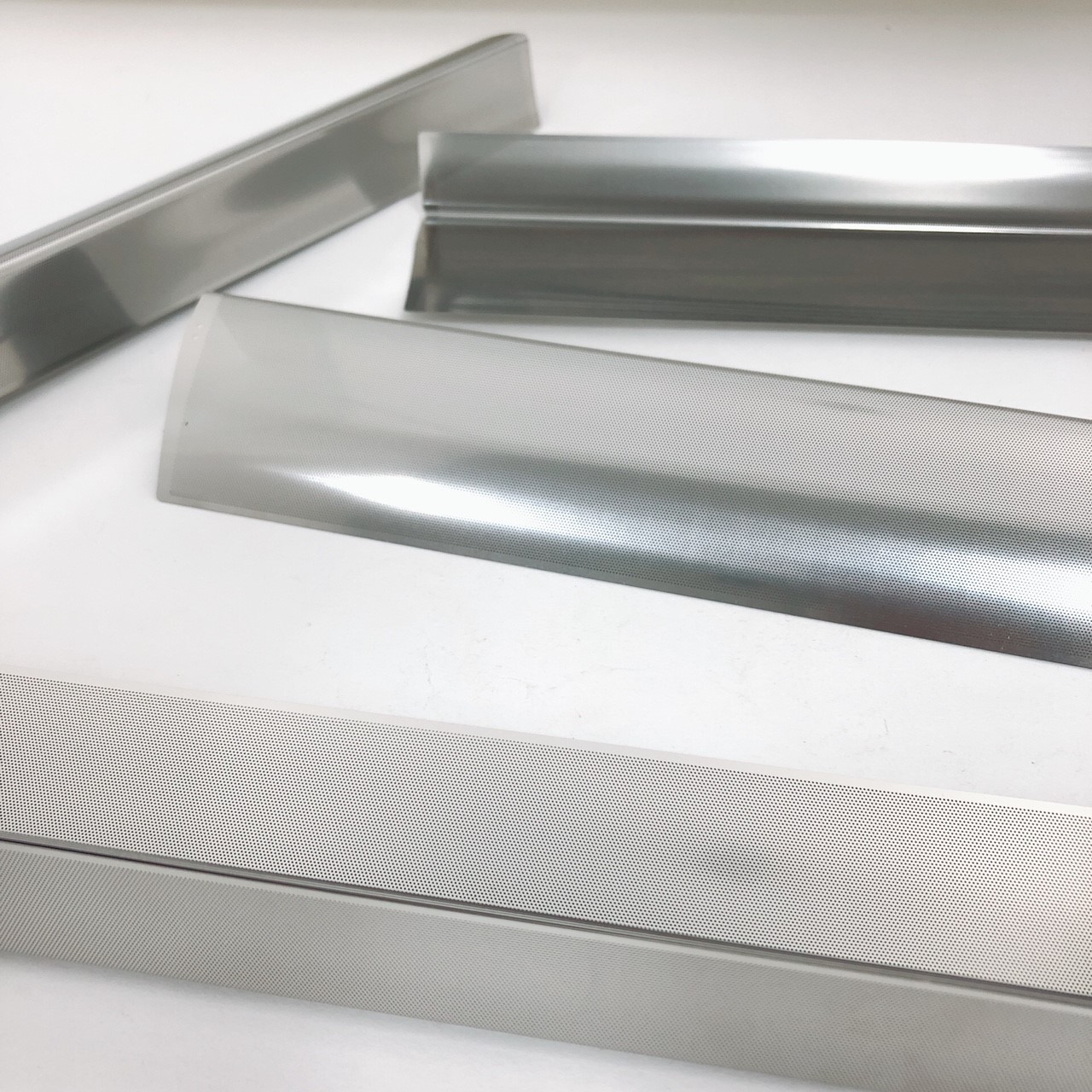

* MonoBlok™ Linear injector for improved reliability and lower CoO

-Produces gap fill by separating the reactant and oxidant chemicals into laminar flow with controlled mixing above the surface

-Precise linear deposition zone produces consistent film properties over entire wafer surface

* High throughput due to high deposition rate in bulk film

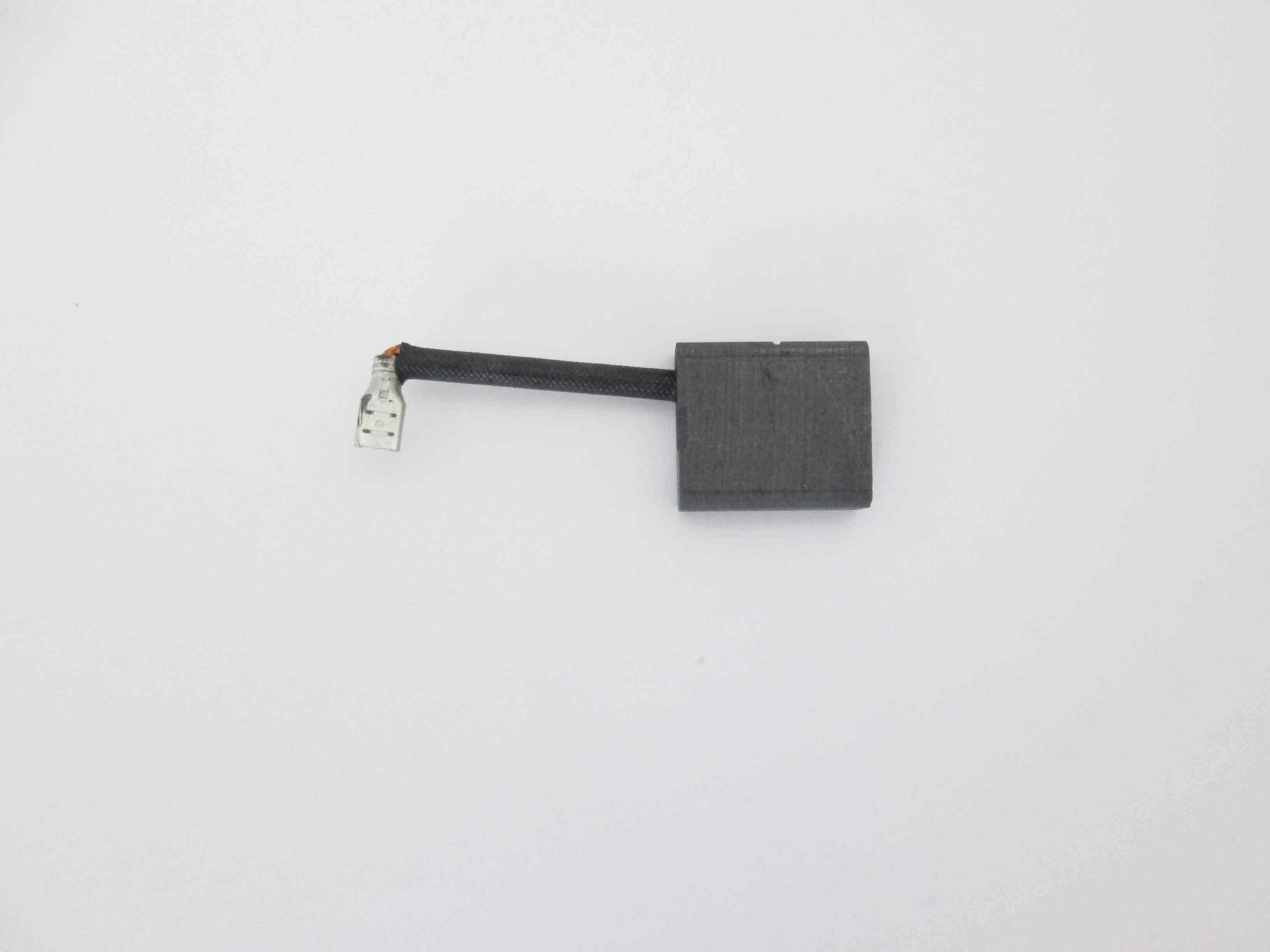

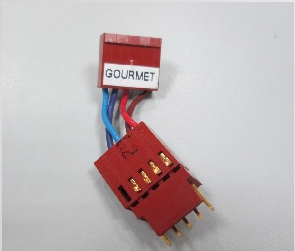

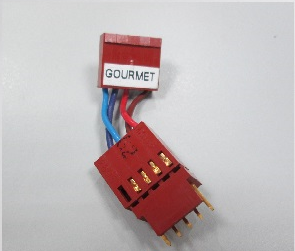

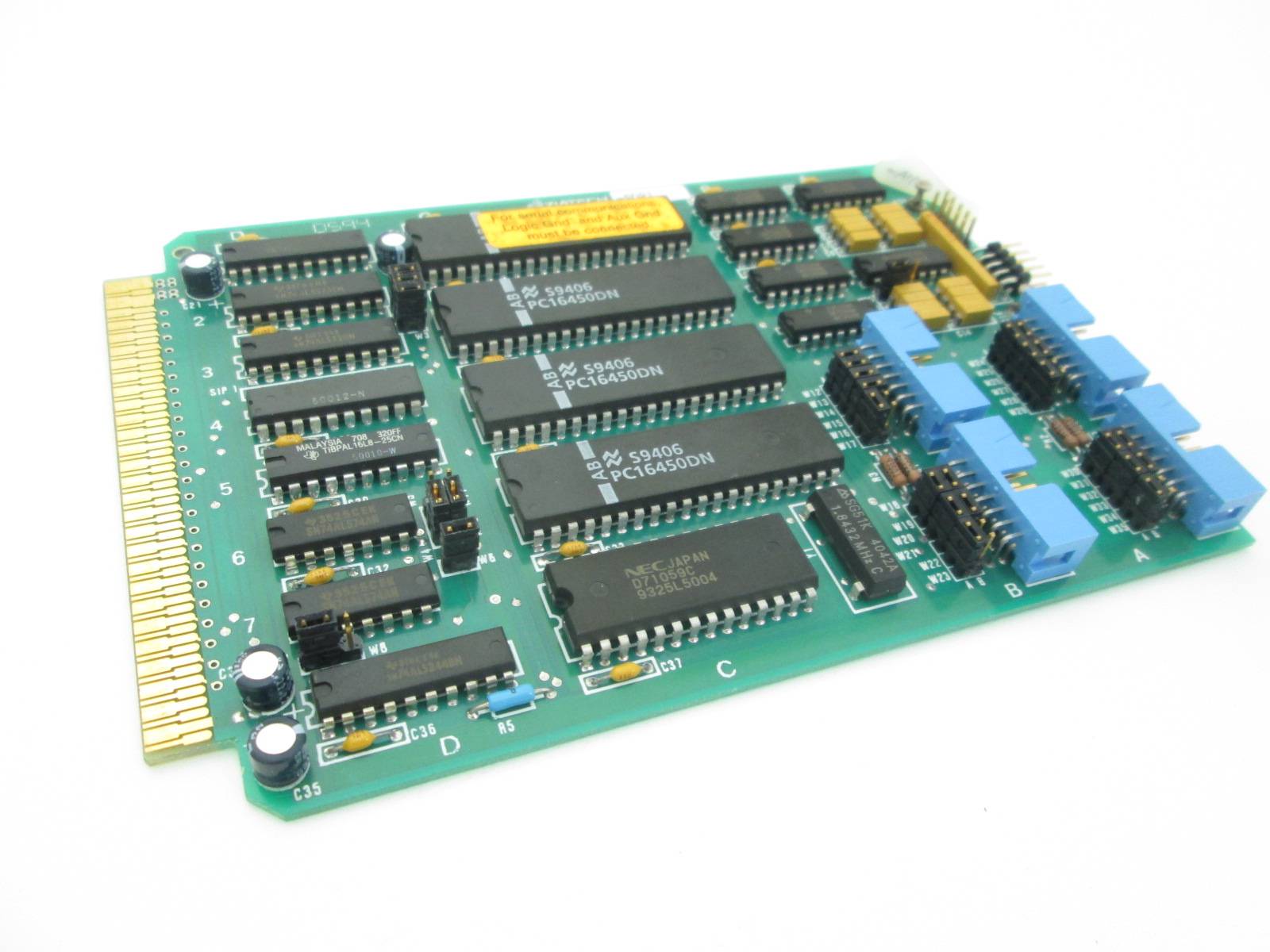

WJ999 & WJ1000 spare parts as below , welcome to contact us!

The WJ-1000T and WJ-1500T TEOS systems deposit doped or undoped silicon dioxide (SiO2) films, created from the TEOS/Ozone CVD reaction. The WJ-1000T and WJ-1500T film applications include shallow trench isolation, capacitor ILD, Bitline ILD, Gate ILD, Sidewall spacer, PSG passivation, IMD gap fill and capacitor core oxides. The WJ-1000H Hydride systems deposit doped or undoped silicon dioxide (SiO2) films, created from the Silane/Oxygen CVD reaction. Typcially, the silicon dioxide film is doped with Boron, Phosphorous and/or Germanium. Examples of the broad range of WJ-1000H semiconductor applications include pre-metal dielectric, interlayer dielectric and numerous spacer oxide.